Cantilever racking is a versatile, high-capacity storage solution designed for long, bulky shaped loads such as timber, pipes, sheet metal, and extrusions. Unlike conventional pallet racking, cantilever systems have no front columns, giving operators unobstructed access to materials. In this guide you will learn:

- What cantilever racking is and why it is unique

- Key system components and configurations

- Benefits and use cases across industries

- Installation, safety, and maintenance best practices

By the end, you will know exactly how to leverage cantilever racking to maximise floor space, improve picking efficiency, and scale your warehouse operations.

What Is Cantilever Racking?

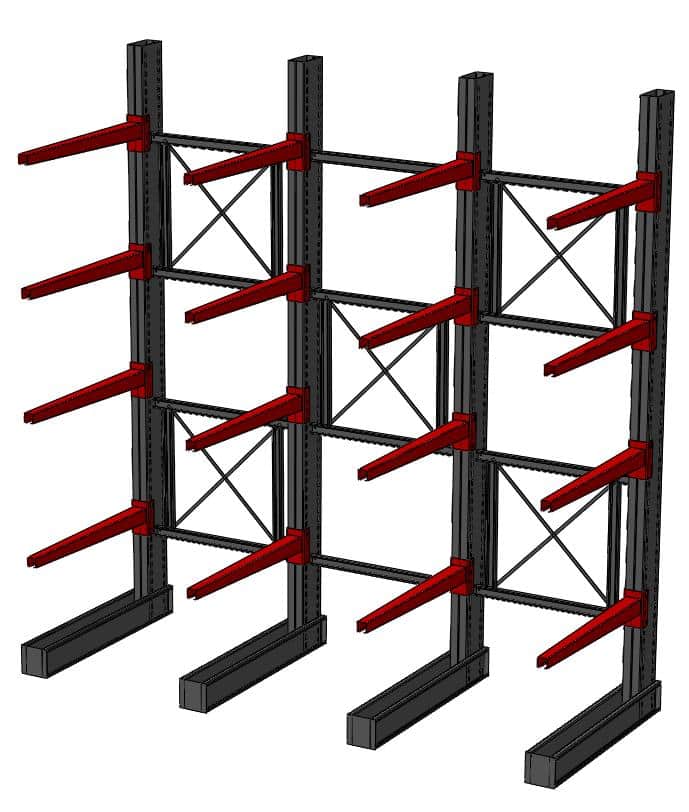

Cantilever racking is composed of vertical uprights, horizontal arms, base plates, and braces.

It uses the principle of counterbalance—heavy loads on the arms are offset by a sturdy base and structural braces with a tapered finish—so no front columns are required.

Key Components

Uprights: Heavy-duty steel columns that carry weight from arms to the floor.

Arms: Adjustable horizontal beams welded or bolted to uprights to support loads.

Base Plates: Floor-mounted anchors that stabilise each upright.

Braces: Diagonal or horizontal members that tie uprights together for rigidity.

How Cantilever Racking Works

The load is placed on one or more arms; the base plate and brace system absorb the overturning force. This design provides full access to each arm position—ideal for hand-loaded or forklift-handled long goods.

Types of Cantilever Racking

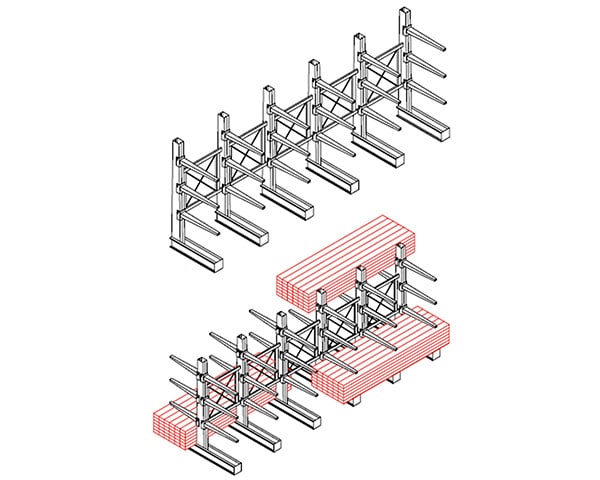

Conventional Cantilever Racking

A fixed-aisle system with open access. Best for medium-density operations where forklifts travel down wide aisles.

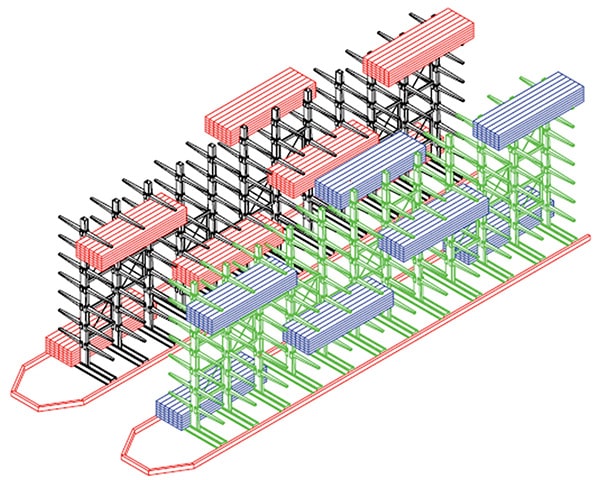

Guided-Aisle Cantilever Racking

Equipped with floor rails and fork-mounted guide rollers for precise navigation down narrow aisles. Ideal for maximising bay density.

Free-Path Cantilever Racking

No floor rails required—uses vehicle-mounted electronic guidance to steer forklifts. Offers ultimate layout flexibility.

Benefits of Cantilever Racking

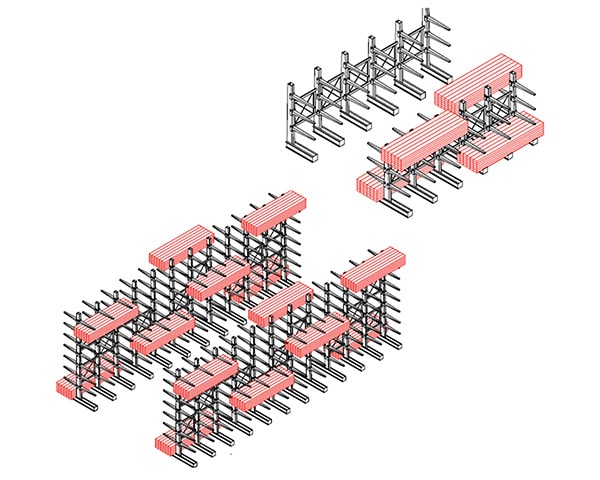

Unobstructed Access: Forklifts and manual handlers can approach loads directly without column interference.

Customisable Bay Design: Arm lengths, heights, and capacities can be tailored to your exact loads.

High Load Capacities: Heavy-duty arms support weights from 500kg to several tonnes per arm.

Scalability: Easily add uprights and arms to expand storage as your business grows.

Improved Picking Efficiency: Open-front design and clear sightlines speed up order fulfilment.

Installation and Safety Considerations

Site Preparation

Floor Flatness: ensure that the floor the racking is to be placed on is levelled.

Load-Bearing Capacity: Verify concrete strength; reinforce if necessary.

Environmental Factors: Consider moisture, temperature, and dust control.

Installation Steps

Lay out base plates and mark anchoring points.

Erect uprights, plumb and secure with bolts.

Fit arms at specified intervals; torque arm fixings to manufacturer spec.

Install braces and cross-members to tie uprights together.

Conduct a proof load test before putting into service.

Safety Best Practices

Perform quarterly inspections for loose bolts, corrosion, and damage.

Never exceed the rated arm capacity.

Train staff on correct loading angles and weight distribution.

Use end-of-arm protectors or stoppers to prevent load overhang.

As a full manufacturing member of SEMA all our racking solutions including Cantilever Racking and Pallet Racking are designed and manufactured following SEMA and Health & Safety at Work 1974 racking regulations.

Maintenance Tips

Visual Checks: Monthly inspections by your PRRS for cracked welds or bent arms as catching the early signs can help in the long-run.

Lubrication: Grease connection points annually to prevent rust.

Floor Surface Care: Keep aisles clean to avoid forklift damage to rails or base plates.

Book Annual Inspections: To ensure the longevity of your purchase and keeping the workplace up and running, we always emphasise the importance of booking a racking inspection with a SARI (SEMA Approved Racking Inspector).

Ready to transform your storage footprint? For a free warehouse audit and bespoke cantilever racking proposal!