Understanding Racking Load Labels

In warehouse environments, racking load labels play a crucial role in maintaining safety standards and ensuring compliance with regulations. These labels provide essential information regarding the safe loading capacity of racking systems, helping to prevent accidents and protect both personnel and inventory. The information is vital and safe loading practices should always be adhered to.

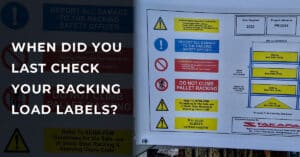

Racking load labels are commonly presented as stickers or signs which are attached to racking structures that provide clear information about the maximum load capacity for each level or section of the racking. This includes details such as weight limits per shelf or bay, as well as any specific loading instructions or precautions. This is to create a safer working environment and to protect inventory.

Racking Load Label Inspections

Racking load label checks are standard practice within your Health and Safety racking inspection. Along with multiple examinations your Environmental Health Officer will automatically check your Load Labels when visiting your site – an obvious fact but so often overlooked.

IT IS YOUR LEGAL OBLIGATION TO ENSURE THAT YOU HAVE THE CORRECT LOAD DATA DISPLAYED ON YOUR RACKS

The Health & Safety at Work Act requires you to:

1. Provide safe systems and equipment for using, handling, storing and transporting articles and substances.

2. Provide the relevant information, instruction, training and supervision as is necessary to ensure the Health & Safety at work of employees

Following the installation of our Racking Systems, Stakapal offers all customers the facility to book an annual SEMA Racking inspection as part of our ongoing support services. All inspections are undertaken on your behalf by our own in- house trained SARI’s (SEMA Approved Racking Inspectors). A full detailed report will be provided meeting the HSE’s requirements on all racking inspections.