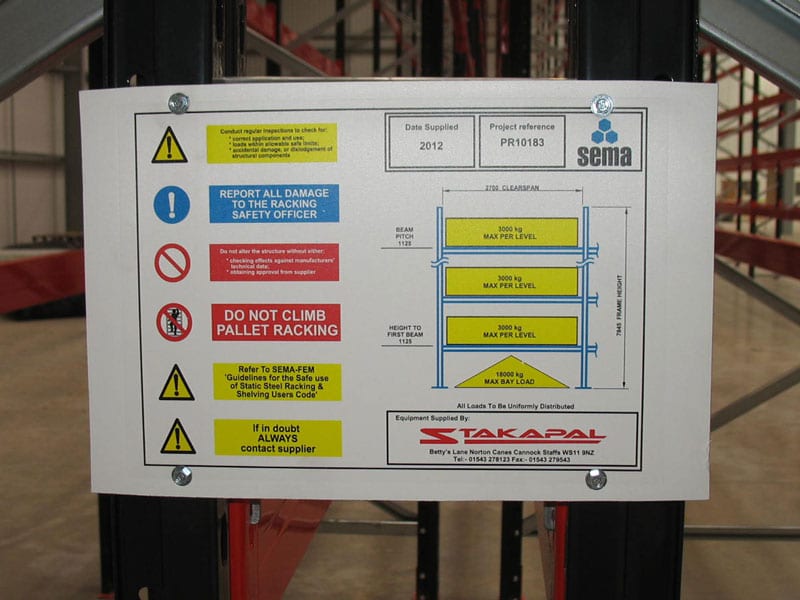

Warehouse safety starts with ensuring your load labels for pallet racking systems are fit for purpose and capable of supporting the load capacity that they are designed for.

To achieve this, load testing and load notice certification play a crucial role in determining how much weight the pallet rack can hold whilst maintaining workplace safety, regulatory compliance, and operational efficiency.

Stakapal provide loading data, as standard, with every new racking structure purchased. As a full manufacturing member of SEMA we prioritise safe working warehouse environments.

How do we test racking capacity?

Specifically, load testing involves placing controlled weight onto the materials that will be used to manufacture the warehouse racking to assess its strength and stability under maximum load conditions, determining its weight capacity.

At Stakapal, we have our own in-house testing facility and Research and Design team, who are responsible for testing every component that we manufacture. As a result of this testing process, we can ensure the safety of every racking system we supply can safely handle the weight limit on its load notice.

Need an inspection? Book here.

Annual inspections of racking are usually a requirement of insurance. Choosing a qualified SEMA Approved Racking Inspector SARI can help save you money and time.

EXCELLENTTrustindex verifies that the original source of the review is Google. Extremely professional company supply and fit high quality pallet racking. Fitting team were excellent ensuring positioning was exactly has required. Arrived on time and completed the work to an exceptional standard.Posted onTrustindex verifies that the original source of the review is Google. Great Service from Sam, Owen and Richard! Would highly recommend

Owner's reply

Hi Nick, thank you so much for your kind feedback! We are really glad to hear you had a positive experience. It means a lot to us!Posted onTrustindex verifies that the original source of the review is Google. Great guys who installed our rack very friendly and helpfull A1 ,steve hart perrinandrowe

Owner's reply

Hi Steven, thank you so much for your kind feedback! We are really glad to hear you had a positive experience. It means a lot to us!Posted onTrustindex verifies that the original source of the review is Google. Excellent service, quality and communication from the very start to finish. They will support you and guide you, query and give you pushback if something does not make sense, but ultimately help and respect your decisions too to make it the best success it can be. They are also very flexible with timelines to work around other projects in the building site, whilst going the extra mile and fair. A big shoutout especially to James and the wider team.

Owner's reply

Hi Noam, Thank you so much for your great feedback! We are glad you had a good experience and would love to hear from you again soon. We look forward to serving you again!Posted onTrustindex verifies that the original source of the review is Google. The team we had here at James Latham Hemel Hempstead were great. Lead by Sam they worked fast and were very polite and very efficient

Owner's reply

Hi, Thanks so much for your great feedback! We’re glad you had a good experience and would love to hear from you again soon. We look forward to serving you again!Posted onTrustindex verifies that the original source of the review is Google. We recently had our racking installed by Stakapal and couldn’t be more pleased with the service. From start to finish, the team was quick, efficient, and highly professional. Everything was carried out exactly as planned, and they even made some on-the-spot adjustments to tailor the installation to our needs on the day. The whole process was smooth, well-organised, and completed to a very high standard. We’re extremely happy with the results and would highly recommend Stakapal to anyone looking for reliable and expert racking solutions.

Owner's reply

Hi Damian, Thank you so much for your great feedback! We’re glad you had a good experience and would love to hear from you again soon. Don’t hesitate to reach out if there's ever anything we can do for you.Posted onTrustindex verifies that the original source of the review is Google. Would like to thank Stakapal for another efficient inspection of our racking system at Hanson plywood, its great that we have a fantastic working connection with each other. Rob Yeomans who visits our site for any alterations is very helpful, polite and also very good at his profession, we are very happy to continue our good working relationship for many years to come.

Owner's reply

Hi John, Thank you! Your kind words have really made our day. We are thrilled you are happy with our service and we look forward to serving you again!Posted onTrustindex verifies that the original source of the review is Google. We had racking fitted in our timber yard and the 2 fitters were brilliant expert job done and very professional, would recommend .

Owner's reply

Hi Mark, Thanks so much for your great feedback! We’re glad you had a good experience and would love to hear from you again soon. We look forward to serving you again!Posted onTrustindex verifies that the original source of the review is Google.

Owner's reply

Hi Steven, thank you so much for your great feedback! We are glad you had a good experience and would love to hear from you again soon.

Why are Load Notices important?

- Safety Assurance: The loading data is available quickly and clearly. So there is no question about the weight that the storage system can handle, limiting accidents caused by overloading.

- Regulatory Compliance: Meet industry standards and legal requirements. Displaying the pallet racking load capacity is usually a requirement for insurance, and void load notices often mean void insurance.

- Operational Efficiency: Avoid disruptions caused by equipment failure, such as damaged racks due to overloading.

- Extended Lifespan: Identify and address potential issues early to prolong the system’s durability.

What Is Involved in load testing for certification?

Load label certification ensures that your racking system complies with industry health and safety standards, such as:

- The Storage Equipment Manufacturers Association (SEMA) guidelines.

- European standards like EN 15512.

- Manufacturer-specific recommendations.

You can also complete a Rack Safety Awareness course to help with health and safety compliance.

Maintain Compliance with Stakapal

Need help with your load labels for pallet racking? Get in touch with our expert team of design engineers for advice and replacements.

Stakapal are full members of SEMA (Storage Equipment Manufacturers Association), with our installation and inspection teams fully SARI (SEMA Approved Rack Inspector), and SEIRS (Storage Equipment Installers Registration Scheme) registered.

How often should Load Labels be checked?

Loading information should be visible on your racking all the time, with regular checks that they are still valid.

Here are some examples of when they are always required to be replaced:

- The installation of a new storage solution.

- After any modifications or repairs.

- When they are missing or indecipherable.

Ultimately, by making load data, testing and certification a priority, businesses can minimise risks, protect employees, and ensure the longevity of their pallet racking systems. A proactive approach to safety benefits not only the warehouse but also the overall success of the organisation.

It is important that there is a Person Responsible for Racking Safety (PRRS) on site who is checking the racking for risk, damage or repairs, and racking systems are inspected by a SEMA Approved Racking Inspector (SARI) annually. This can help maintain compliance and prevent structural failure or instability, providing peace of mind for business operators.