What the HSE Expects from Your Warehouse Racking System

Warehouse safety is no longer a “nice to have” — it is a legal obligation. The Health and Safety Executive (HSE) sets out strict guidelines to ensure your storage systems do not pose a risk to staff or stock. At Stakapal, we work closely with SEMA and HSE protocols to help businesses meet these responsibilities efficiently and effectively.

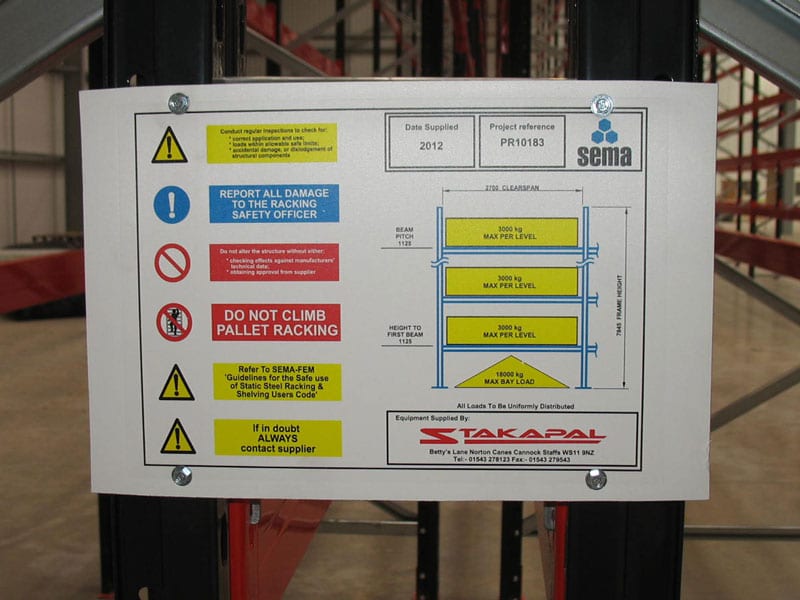

Load Notices – A Legal Must

Every racking system must display clear, visible load notices in order to adhere to the HSE warehouse racking regulations. These should include:

- Maximum load per bay and level.

- Manufacturer details.

- Date of installation or last inspection.

Stakapal supplies bespoke load signage tailored to your configuration, ensuring compliance is as simple as visibility. We also offer replacement load notices if your current load notice is damaged or if the information on the notice has become barely visible.

Regular Inspections – Backed by SEMA & HSE

Under HSE guidance (HSG76), employers must ensure their racking systems are:

- Maintained in safe condition.

- Inspected regularly by a competent person – in most cases this is a designated PRRS onsite.

Stakapal’s SARI-approved inspectors carry out thorough audits that identify red and orange risk levels. We offer detailed reports to guide repairs and improvements.

As a full manufacturing member of SEMA all our racking solutions including Cantilever Racking and Pallet Racking are designed and manufactured following SEMA and Health & Safety at Work 1974 racking regulations.

Reporting Incidents & Taking Action

If a racking collapse or near-miss occurs, it must be:

- Reported to HSE under RIDDOR

- Documented and photographed

- Assessed by a competent professional

Staff Training & Responsibility

Employees must be trained to:

- Report visible damage

- Not overload racking

- Follow correct stacking procedures

We provide guidance on expert safety training and toolkits to empower your staff.

Stay Compliant with Stakapal

Do not risk non-compliance or workplace accidents. Let Stakapal audit your systems and keep you aligned with HSE warehouse racking regulations.